STRENINN PROCESS

A-Class Marble continues the legacy of luxury marble by constantly adding new innovations for creating the state-of-the-art technology to safeguard the marble for eternity. Revolutionary StrenInn Technology is blend of the words ‘Strength’ and ‘Innovation,’ which are the two driving forces behind its creation. The team adheres to the unique StrenInn process, so the marble retain its durability, high quality finish and luster even after years of use.

TECHNOLOGY PARTNERS

1. IMPORTING & OFFLOADING OF BLOCKS

The best marble blocks are imported & offloaded in the gantry yard at the state-of-the-art processing unit in Kishangarh, Rajasthan.

2. CLEANING & DRESSING OF BLOCKS

The marble block goes through a high-tech cleaning and dressing process to dispose the impurities and even out all sides of the block.

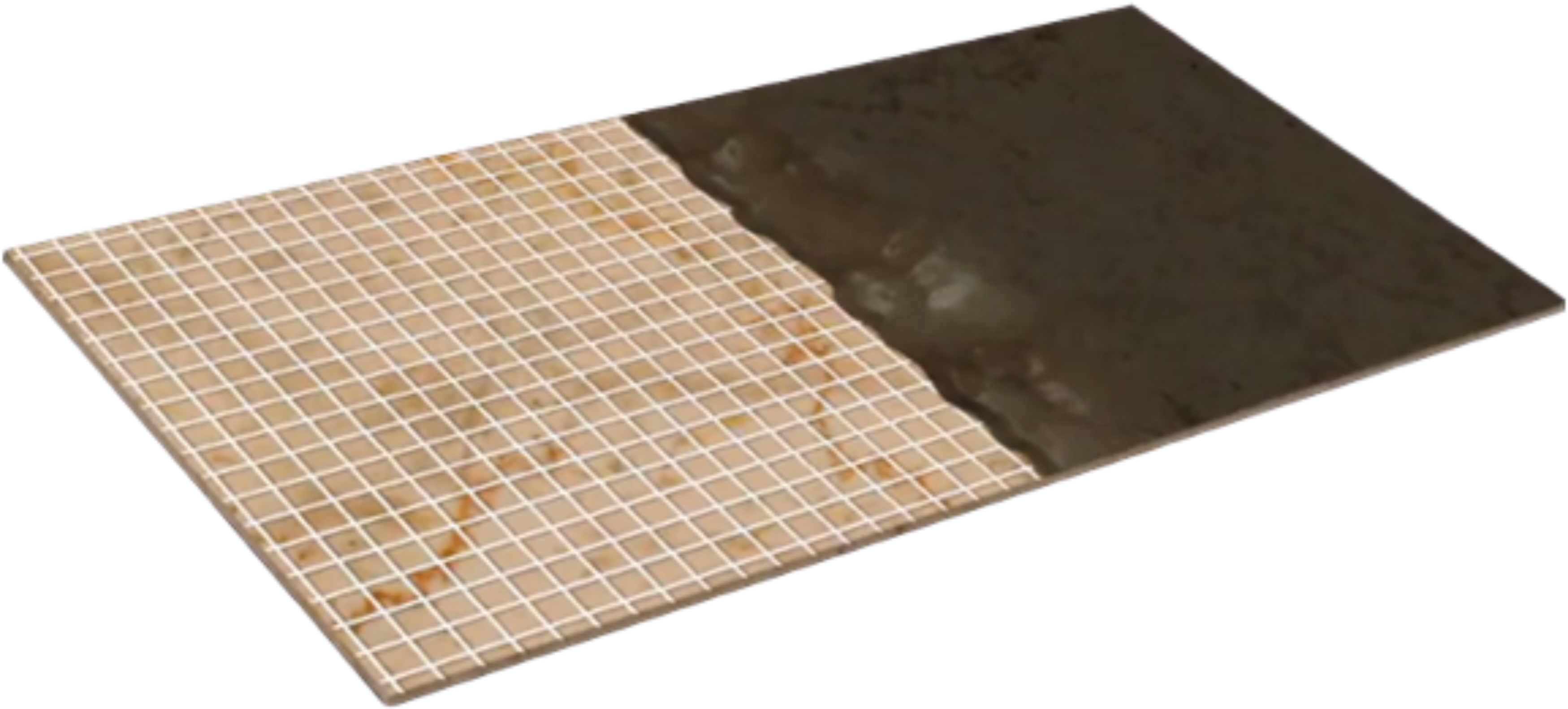

3. BLOCK REINFORCEMENT:

The block undergoes grinding & blowing process to smooth its surface and remove dust particles.

Fibreglass net is applied on every side of the block and then covered with sheet.

Tenax specially prepared epoxy is applied through the installed pipes to penetrate inside the block.

The block undergoes vacuum process to boost its durability and ensures that every nook and cranny of the block is sealed shut.

THIS PROCESS INCREASES THE STRENGTH & DURABILITY OF THE BLOCK

4. SLAB CUTTING PROCESS

The Gangsaw machinery cuts the reinforced blocks inch perfect as per the standard International dimensions of 18+ mm & 20+ mm thickness.

Thickness: 18+ mm & 20+ mm We also create bespoke dimensions as per the client’s specifications

5. SLAB REINFORCEMENT:

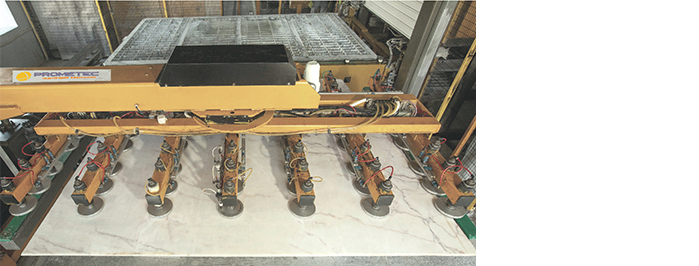

Prometec - Robotic Machinery transfers the slabs to the epoxy machine and heated in heating chambers to remove moisture from the slab.

Fibreglass net is applied on backside of the slab for reinforcement.

Italian epoxy is applied on backside of the slab.

Slabs are heated in heating chambers for deeper penetration. Italian epoxy is applied again on backside of the slab.

Robotic machinery reverse and shifts the slab to the cleaning machine. Grinding machine is used with water jets to remove resin drops and dust particles for a smooth surface. Slabs are then heated in heating chambers for dying.

6. BOTH SIDE EPOXY APPLICATION

Italian epoxy is applied on front side of the slab to boost its strength and then kept in storage for penetration. Italian epoxy is applied again on front side of the slab for higher density. Slabs are heated in heating chambers.

7. POLISHING OF SLABS

Breton Polishing machinery is used to enhance the visual aesthetics and shine of the slab resulting with endless choice of bespoke ï¬nishes and textures like polished, honed, leather and many more

8. QUALITY CHECK

Each product undergoes a rigorous sets of quality checks and tests at every step.

THE FINAL MASTERPIECE

Benefits Of Streninn Process